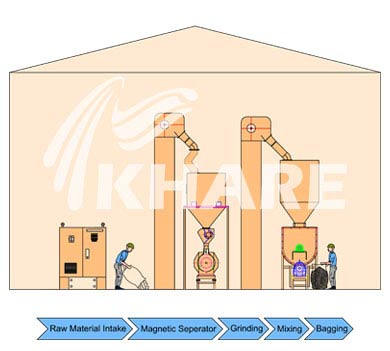

Mash Feed Plant

Mash Feed Plant is designed to process the feed in mash form to make them suitable for animals & Birds. This plant contains hammer mill or grinders to grind the ingredients and convert it in the powder form in right proportions for availing homogenous feed. It comes with a reliable magnetic separator or Cascade magnet to separate ferrous material like iron particles etc., from the raw material. The Plant is designed such that it emit minimum dust, vibration and noise.